salt spray Test chamber in Zunheboto

Corrosion Test Chamber or salt spray Test chamber in Zunheboto is one of the most accurate instruments for measuring the corrosion resistance of coating. Hence Salt spray chamber plays a very important role to test the specimen and analyse the quality of material being used by us for manufacturing. While In industries the material is exposed to various types of climatic conditions and chemical fumes which develop corrosion of components and parts.

Overview: salt spray Test chamber in Zunheboto

While the tested product has been specifically designed to access the rust proof ability of components to withstand corrosion due to atmospheric condition. Hence It Provides complete flexibility in simulation of a real life weathering conditions. Therefore salt spray tester is designed as per standards which includes following standards

- ASTM B117

- ISO:9227

- JIS:2371

Equipment?s used:

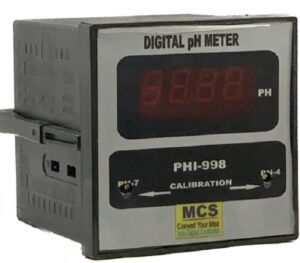

1.?Temperature Controller :- To Control temperature of Humidity / Chamber for heating of fogged water. with Auto Cut system to maintain temperature with in specified range 32 to 37 degree Celsius.

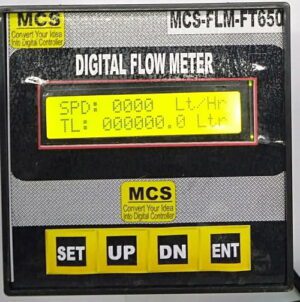

2. Hour Meter :- To observe / inspect condition of test samples periodically and recording long with time At least 3 digits in Hour and 2 digits in minutes

3. AIR SUPPLY :- The air supply must be free from Oil, Dust, , the air supply / pressure must be maintain in such a way. so that salt fog occurs, Pressure must be 1 Kg +/- 0.2 Kg

4. ATOMIZATION AND QUANTITY OF FOG :- The fog shall be such that for each 80 cm2 (4 Inch Funnel ) of horizontal collecting area. there will be collected from 1.0 to 2.0 mL of solution per hour based on an average run of at least 16 h

Our other models in this catogary: salt spray Test chamber in Zunheboto

Please Click Here for Details about all Models and those diamentions

- SALT SPRAY 294 Liter

- SALT SPRAY 324 Liter

- SALT SPRAY 360 Liter

- SALT SPRAY 400 Liter

- SALT SPRAY 420 Liter

- SALT SPRAY 480 Liter

- SALT SPRAY 540 Liter

- SALT SPRAY 640 Liter

- SALT SPRAY 800 Liter

- SALT SPRAY 1000 Liter

FEATURES: Hence the main features of Salt Spray Test Chamber are

- Saline Solution Label Low in Reservoir (Main Tank for water accumulation) Tank Indication is provided at front panel. Hence Auto Fill and Level System also available.

- Auto fill and label maintaining System for Reservoir Saline tank. Hence Sensors available for maintaining water level between high and low levels.

- Chamber Waste water Auto Drainage Control Systems. (No manual drain). Hence Sensors are Provided to Control the Drainage of waste water automatically

- Fully Automatic Temperature Controller double display for Heating of Water. Hence You Just set the Temperature Required Generally 32 to 37 degree. the temperature of chamber and water automatically maintain.

- Temperature over Heat Warning Indicator on front panel. Hence this Indicator also provided for Signal Only. While You have to do nothing it will maintain automatically. Hence if not maintain within half hour than check its thermocouple may break of some technical fault or in Temperature Controller unit. Hence You Don’t Worry it covered under warranty for one year and repairable after warranty period. So just Contact with us we send new one for replacement.

- Hence In Built Temperature Settings. While Auto Cut System already discussed in previous discussion.

- Well Insulated Electric Shock Free, anti-Corrosion, Unbreakable Heaters (Nominal Life 10 Years/ No Glass Heater)

- Fogging System Centralized as per ISO 9227 and ASTM B 117 and JIS 2371 Standards.

- Standardized Fogg collection System as per ISO 9227 and ASTM B 117 and JIS 2371 Standards.

- Automatic Fogg Operating System. Hence it Controlled by Process Switch ON / OFF.

- Hour Meter 999 Hours 59.9 Minutes very easy and user friendly setting.

- Advance Technology Atomizer timer.

- Free Maintenance and easy to use operate model.

- Process Complete Buzzer Alarm with Indicator

- Supply 220 VAc

- User Friendly PID setting through Advance Hysteresis settings.

- Warranty 1 Year

Reviews

There are no reviews yet.